Dynamic Balancer Technology is an application-specific technology that makes machines run more evenly and efficiently. So basically, it checks that everything is tuned and situated correctly for the machine to function properly. But why is Dynamic Balancer Technology so important for machines and how does it work

Dynamic Balancer Technology. It turbocharger belt driven reads any shakiness or in the machine, and then adjusts to correct it. It makes the machine more efficient and increases its longevity. DYNAMIC BALANCER TECHNOLOGY is present in many machines such as cars, aircraft, and even toys!

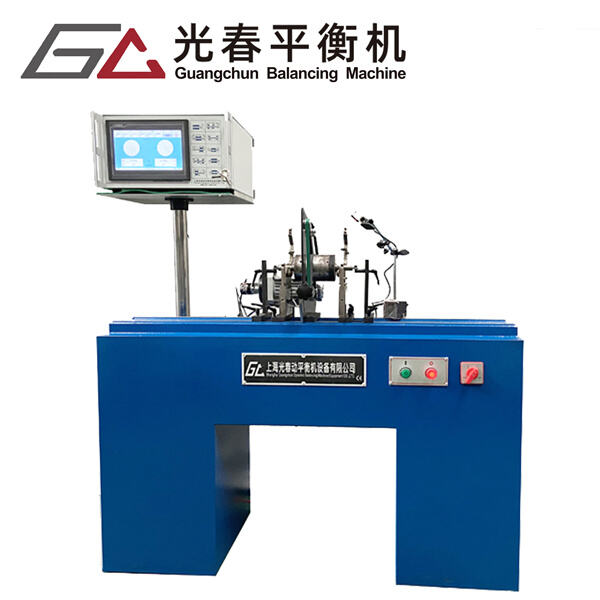

Dynamic Balancer Technology ensures everything is in balanced motion so machines work better. If one half of a machine is heavier than the other and they are not balanced, it Universal joint balancing machine will shake and wobble, and then it will not work correctly. Dynamic Balancer Technology catches these shakes and wobbles, and fixes them, helping the machine run smoother and better.

Vibration is the shaking or moving rapidly back and forth of something. In a machine, excessive vibration can increase wear or even lead to failures. It Dual drive balancing machine can be risky and costly. Dynamic Balancer Technology eliminates vibration by ensuring everything is balanced. Dynamic Balancer Technology identifies and corrects for any shakes making sure your machines can deliver a safer operation at the peak of their performance.

Precision manufacturing is about building things with a great deal of care and accuracy. It’s vital in lots of industries, including corporate such as producing cars or airplanes. Dynamic Balancer Technology is a very important tool for the precision manufacturing sphere because it helps ensure that all the machine parts are perfectly located and balanced. In this way, the machine can function effectively and safely. The Drive shaft dynamic balancer makes it a lot easier to make things carefully.

We all know that to be as efficient as possible, anything must be balanced, which is what the dynamic balancer technology does. Machine parts wear out more quickly and can breakdown if not in balance. This incurs high repair costs and downtime for the machine. Dynamic Balancer Technology - preventing these Cross flow blade balancer issues by identifying and correcting imbalances before they escalate. It keeps machines functioning properly for extended periods of time.

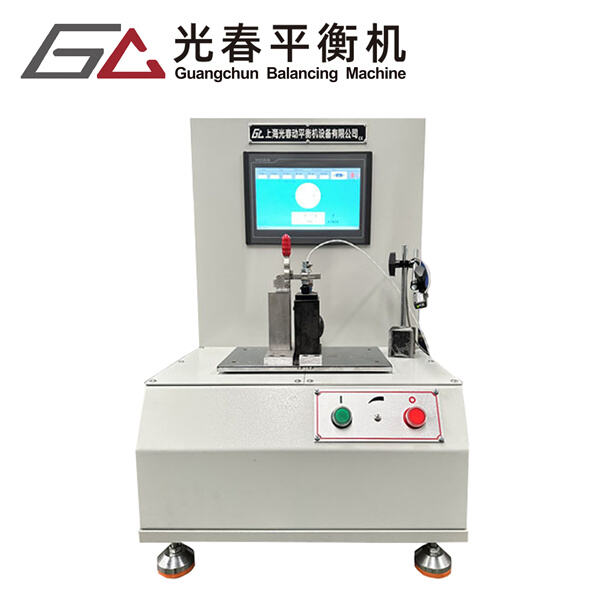

Our product has been thoughtfully designed with users' habits and needs in mind. Whether it's the mechanical structure design, testing system development, or ease of operation, we strive for perfection in every aspect. Additionally, we place great emphasis on product performance and quality, employing advanced production processes, high-quality materials, and rigorous quality control measures to ensure that our products excel in use and meet users' expectations. Beyond our standard offerings, we also focus on exploring personalized designs for our products. By providing customized services and comprehensive after-sales support, we not only offer users our products but also help them overcome challenges in product balancing and enhance their work efficiency.

We understand the importance of service, always adhere to the customer-oriented, committed to providing quality service experience. From the initial customer inquiry to product selection, quotation, contract signing, and subsequently to delivery, installation, commissioning, as well as after-sales service, every step is infused with the enthusiasm and professionalism of all company employees. The company continuously innovates its service model and enhances service quality, establishing a comprehensive customer feedback mechanism to promptly collect customers' opinions and suggestions for continuous improvement of products and services. Additionally, the company regularly conducts customer visits and training activities to assist customers in enhancing their equipment operation skills and maintenance capabilities.our company has always followed the "pour all my, do my best, dedicated users, integrity of the world" business purpose, to quality service, superb technology, reasonable price, quality, ensure set Measuring, developing and manufacturing test instruments to meet the needs of different customers.

We have more than ten years of design and manufacturing experience in the field we are engaged in, keeping up with the cutting edge of the industry and mastering the latest in balancing technologies and concepts.Our company possesses strong technical expertise, the engineer team is sourced from Schenck Machinery. The engineers possess the capability to design non-standard equipment and can conduct research and development design according to customer requirements. Most of our equipment assemblers and electrical installers have extensive experience, with over 20 years of field experience. The company has won the trust and praise of its customers and partners with its rich industry experience and outstanding professional capabilities.

Our products are among the best in the industry, and we have high design and production capacity, and provide customized services. Our products widely applied in the fields of motors, fans, pumps, air conditioning, automobiles, household appliances, machine tools, aerospace and ships. All components have a strict supplier access system to provide product protection.The company's products have obtained CE certification and successfully passed the ISO9001:2015 quality management system certification.Balancing machine electric test box using the electric test system is the company's own research and development, and configured with multi-language options, visualization of human-computer interaction interface, so that customers are convenient to operate.