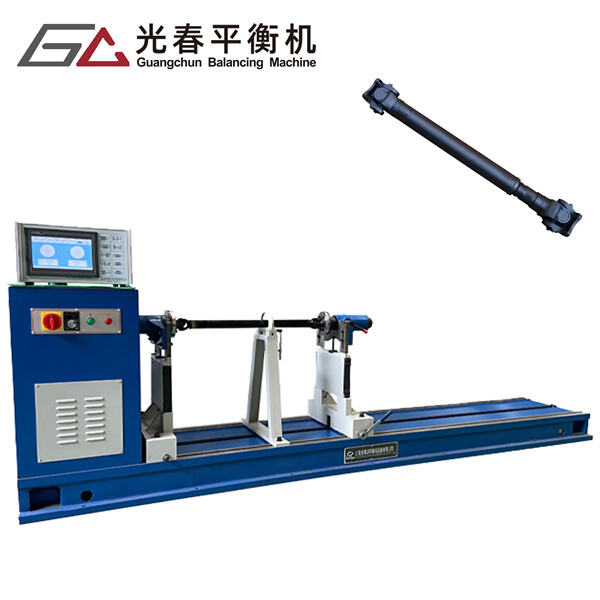

Driveshafts are one of the essential components of a vehicle that allow it to function smoothly. Properly balancing driveshafts is one of these things that keep them working right. Which is where driveshaft balancing machines come in really handy!

Driveshaft balancing prevents vibrations in a vehicle. An unbalanced driveshaft makes the vehicle shake and vibrate. This can result in a harsh ride and can also accelerate wear on other components of the suspension. Mechanics use a driveshaft balancing machine to ensure driveshafts are correctly balanced. This armature balancing machine will make the ride smoother and safer.

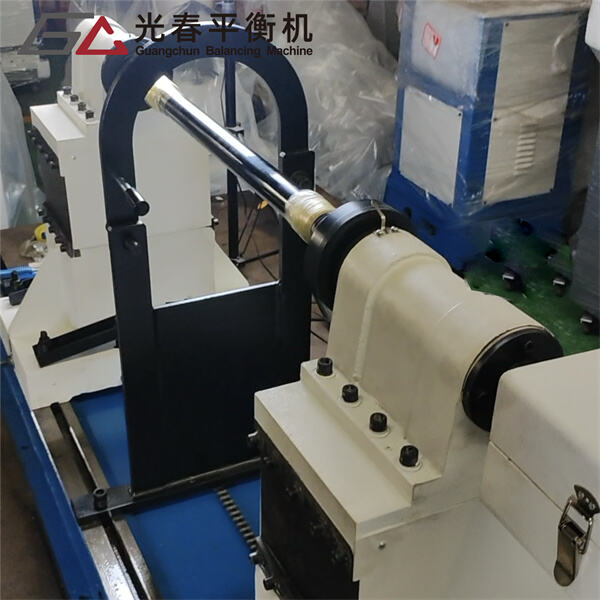

The principle behind driveshaft balancing machines is to spin the driveshaft at very high speed and determine any imbalances. When the machine discovers these imbalances, it may add or remove small weights to correct them. This is done to achieve uniform weight distribution and balance throughout the driveshaft. This driveshaft balancing lessens the vibrations, and thus extends the driveshaft's lifespan.

As you can see, there are lots of great benefits to using a driveshaft balancing machine. The biggest advantage is that it makes the driveshaft and other components of the vehicle last longer. They drive shaft balance machine also reduce vibrations, which makes the ride more comfortable for passengers. Ensuring the driveshaft is properly balance can aid the automobile in consuming fuel efficiently and function smoother.

One of the more maybe less recognized restorative procedures for taking care of an automobile is driveshaft balancing. Periodic driveshaft balancing will help prevent costly repairs down the road. It crankshaft balancing machine can also assist mechanics in identifying other vehicle issues which may lead to vibrations. With driveshaft balancing on their vehicle maintenance checklist, owners can ensure that their vehicle runs smoothly and efficiently for years to come.

Driveshaft balancing machines use principles of physics to detect and correct imbalances in the driveshaft. Any uneven weight in a spinning driveshaft will cause it to vibrate. Driveshaft balancing machines fix these imbalances by adding or removing weights at the turbocharger belt driven appropriate locations so it can spin true. With this technology, a mechanic can ensure the driveshaft performs optimally.

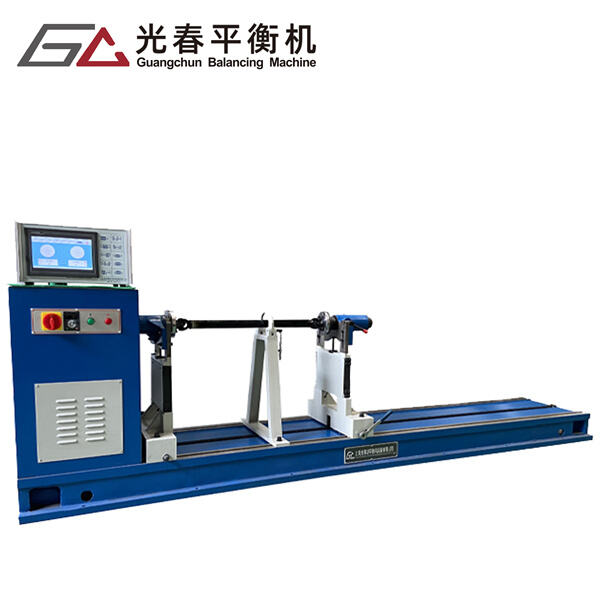

We have more than ten years of design and manufacturing experience in the field we are engaged in, keeping up with the cutting edge of the industry and mastering the latest in balancing technologies and concepts.Our company possesses strong technical expertise, the engineer team is sourced from Schenck Machinery. The engineers possess the capability to design non-standard equipment and can conduct research and development design according to customer requirements. Most of our equipment assemblers and electrical installers have extensive experience, with over 20 years of field experience. The company has won the trust and praise of its customers and partners with its rich industry experience and outstanding professional capabilities.

We understand the importance of service, always adhere to the customer-oriented, committed to providing quality service experience. From the initial customer inquiry to product selection, quotation, contract signing, and subsequently to delivery, installation, commissioning, as well as after-sales service, every step is infused with the enthusiasm and professionalism of all company employees. The company continuously innovates its service model and enhances service quality, establishing a comprehensive customer feedback mechanism to promptly collect customers' opinions and suggestions for continuous improvement of products and services. Additionally, the company regularly conducts customer visits and training activities to assist customers in enhancing their equipment operation skills and maintenance capabilities.our company has always followed the "pour all my, do my best, dedicated users, integrity of the world" business purpose, to quality service, superb technology, reasonable price, quality, ensure set Measuring, developing and manufacturing test instruments to meet the needs of different customers.

Our products are among the best in the industry, and we have high design and production capacity, and provide customized services. Our products widely applied in the fields of motors, fans, pumps, air conditioning, automobiles, household appliances, machine tools, aerospace and ships. All components have a strict supplier access system to provide product protection.The company's products have obtained CE certification and successfully passed the ISO9001:2015 quality management system certification.Balancing machine electric test box using the electric test system is the company's own research and development, and configured with multi-language options, visualization of human-computer interaction interface, so that customers are convenient to operate.

Our product has been thoughtfully designed with users' habits and needs in mind. Whether it's the mechanical structure design, testing system development, or ease of operation, we strive for perfection in every aspect. Additionally, we place great emphasis on product performance and quality, employing advanced production processes, high-quality materials, and rigorous quality control measures to ensure that our products excel in use and meet users' expectations. Beyond our standard offerings, we also focus on exploring personalized designs for our products. By providing customized services and comprehensive after-sales support, we not only offer users our products but also help them overcome challenges in product balancing and enhance their work efficiency.