2025CMES China Machine Tool Exhibition | Shanghai International Machine Tool Exhibition

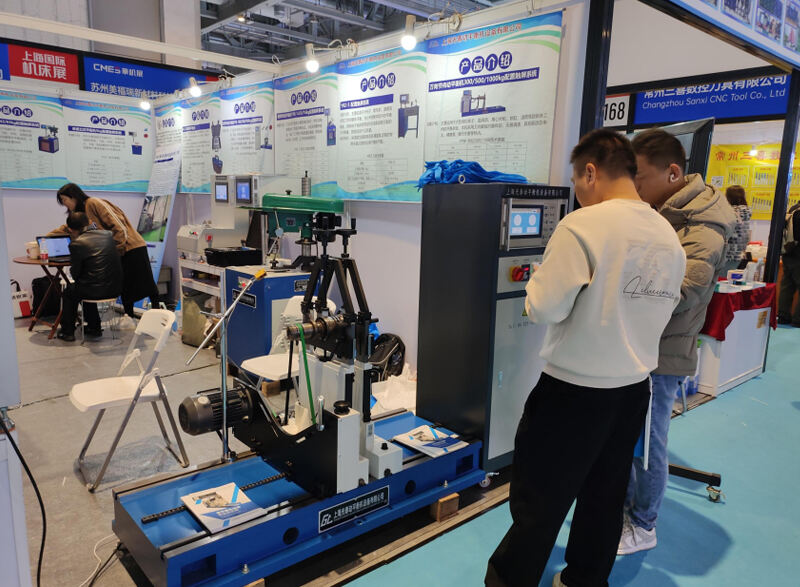

Shanghai International Machine Tool Exhibition At the 10th CMES China Machine Tool Exhibition | Shanghai International Machine Tool Exhibition, a grand gathering of global manufacturing elites, dynamic balancing machine exhibitors have provided multi-faceted effective assistance to the machine tool industry and related fields with their products, technologies, an services. Showcasing Advanced Dynamic Balancing Solutions to Promote the Improvement of Machine Tool Performance Dynamic balancing machine exhibitors have intensively displayed cutting-edge products suitable for the machine tool industry at theexhibition, such as machine tool spindle dynamic balancing machines and machine tool spindle running-in platform equipment.

Take Shanghai Guangchun Dynamic Balancing Machine Manufacturing Co., Ltd., which specializes in the research,development, production, and sales of dynamic balancing machines, as an example. It has actively introduced relevant products to industry professionals in previous exhibitions.

These advanced dynamic balancing equipment can accurately detect and correct the unbalance of the rotating parts of machine tools. For machine tools, the unbalance of rotating parts will lead to increased vibration and noise, seriously affecting the machining accuracy and surface quality, and even shortening the service life of the machine tool. By conducting fine balancing treatment on key components such as machine tool spindles with dynamic balancing machines, vibration can be greatly reduced, making the machine tool more stable during high-speed operation, thus significantly improving the machining accuracy and helping to produce more precise parts to meet the stringent requirements of high-end manufacturing industries such as aerospace, automotive manufacturing, and electronics semiconductors for high-precision machining. Providing On-site Technical Demonstrations and Exchanges to Promote Industry Knowledge Sharing During theexhibition, dynamic balancing machine exhibitors arranged professional technicians to conduct equipment operation demonstrations at the booths, intuitively showcasing the working process and functional features of dynamic balancing machines. They explained in detail the usage methods of the equipment, parameter settings, and balancing strategies for different types of machine tool components, enabling visitors to have an in-depth understanding of the key points of dynamic balancing technology in practical applications. This method of on-site demonstration and explanation not only helps potential customers better understand the products but also provides a platform for learning and communication for industry insiders. Industry practitioners can discuss the dynamic balancing problems encountered in actual production with the technical personnel of exhibitors and share their respective experiences and insights. Through such interactive communication, the dissemination and sharing of dynamic balancing technology knowledge within the machine tool industry are promoted, the technical level of the entire industry is advanced, and new ideas and methods are provided for solving problems in production practice. Helping to Optimize the Production Process and Reduce the Comprehensive Costs of Enterprises From the perspective of the production process, the products and servicesof dynamic balancing machine exhibitors can help enterprises optimize the production process. On the one hand, high-precision dynamic balancing equipment can quickly and accurately complete the balancing correction work. Compared with traditional manual or inefficient balancing methods, it greatly shortens the production cycle and improves production efficiency. On the other hand, the service life of well-balanced machine tool components is extended, reducing the downtime and maintenance costs caused by the need to replace components due to premature damage. In addition, due to the improvement of machining accuracy and the reduction of the defective product rate, enterprises do not need to spend additional resources on reworking or scrapping unqualified products, further reducing production costs. For example, in automotive parts manufacturing enterprises, using advanced dynamic balancing machines to balance key components such as engine crankshafts not only improves production efficiency but also ensures product quality, reduces overall production costs, and enhances the competitiveness of enterprises in the market.

In conclusion, at the CMES China Machine Tool Exhibition | Shanghai International Machine Tool Exhibition, dynamic balancing machine exhibitors have provided comprehensive and effective assistance to the machine tool industry and related enterprises through multiple measures such as showcasing advanced products, carrying out technical exchanges, helping to optimize production,and coordinating logistics support, playing an important role in promoting the technological progress and industrial development of the machine tool industry.